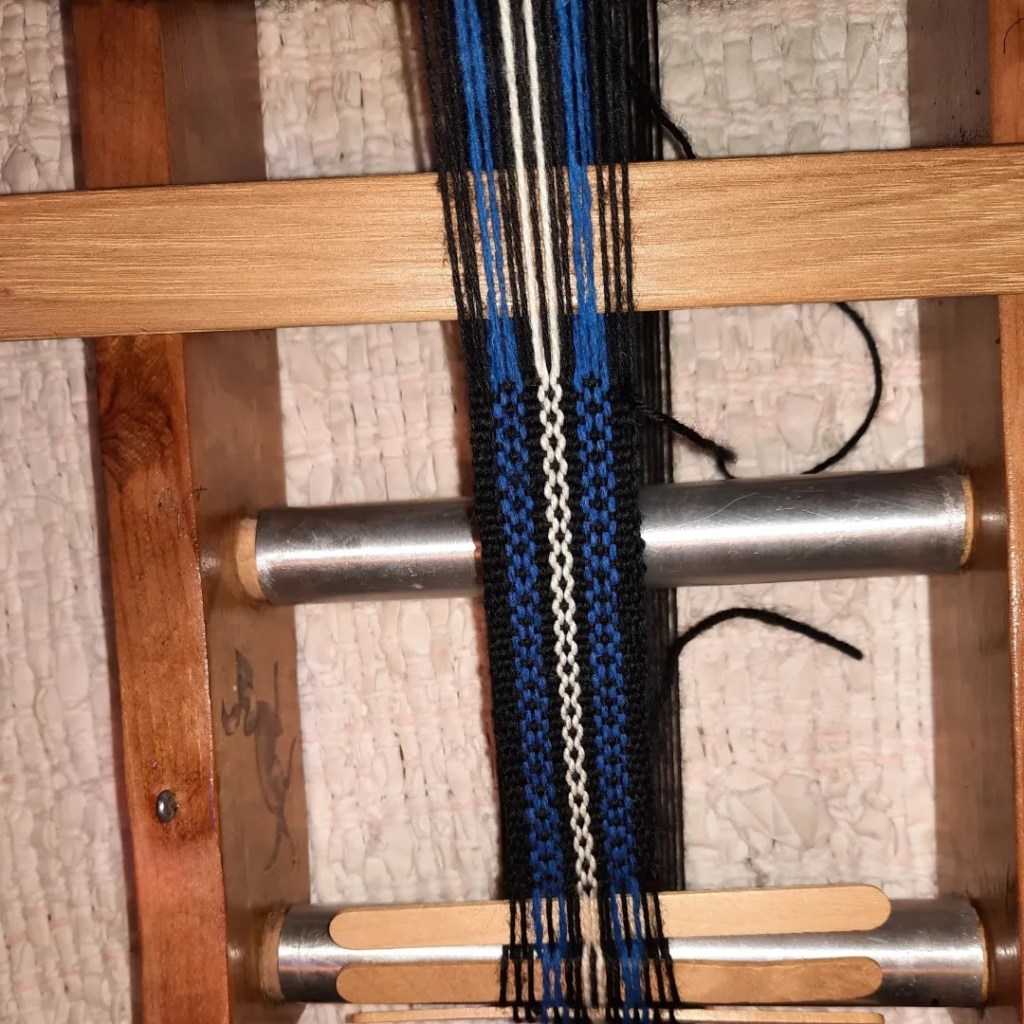

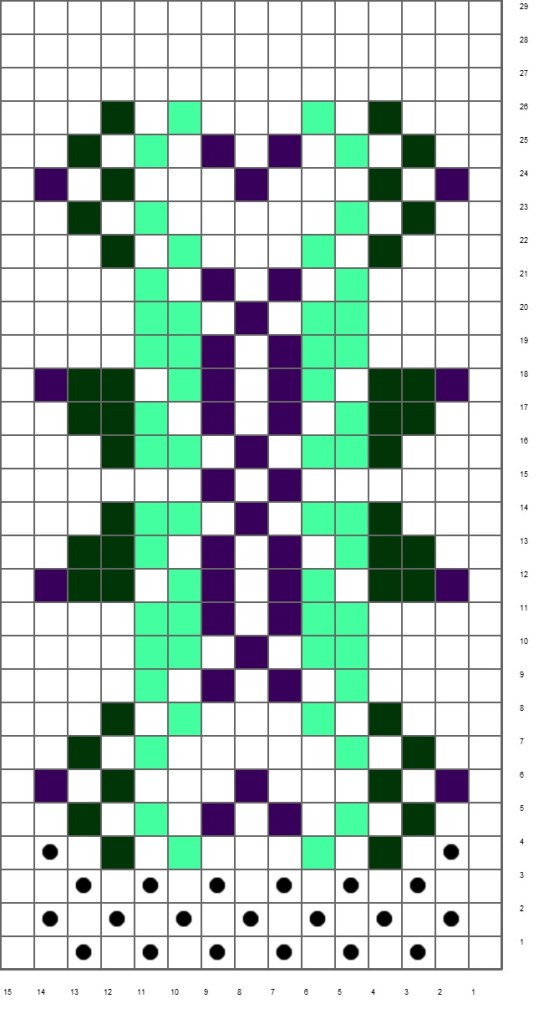

I modified a pattern from the book, The Weaver’s Inkle Pattern Directory, that looks like snowflakes and diamonds. It’s on pg. 77 and is called simply, Baltic-13 2 (it’s actually the one at the bottom of the chart on pg. 77. It’s a neat pattern, but when I started the first one I redrew it so it’s snowflakes and hearts with a 3 row space between each sequence.

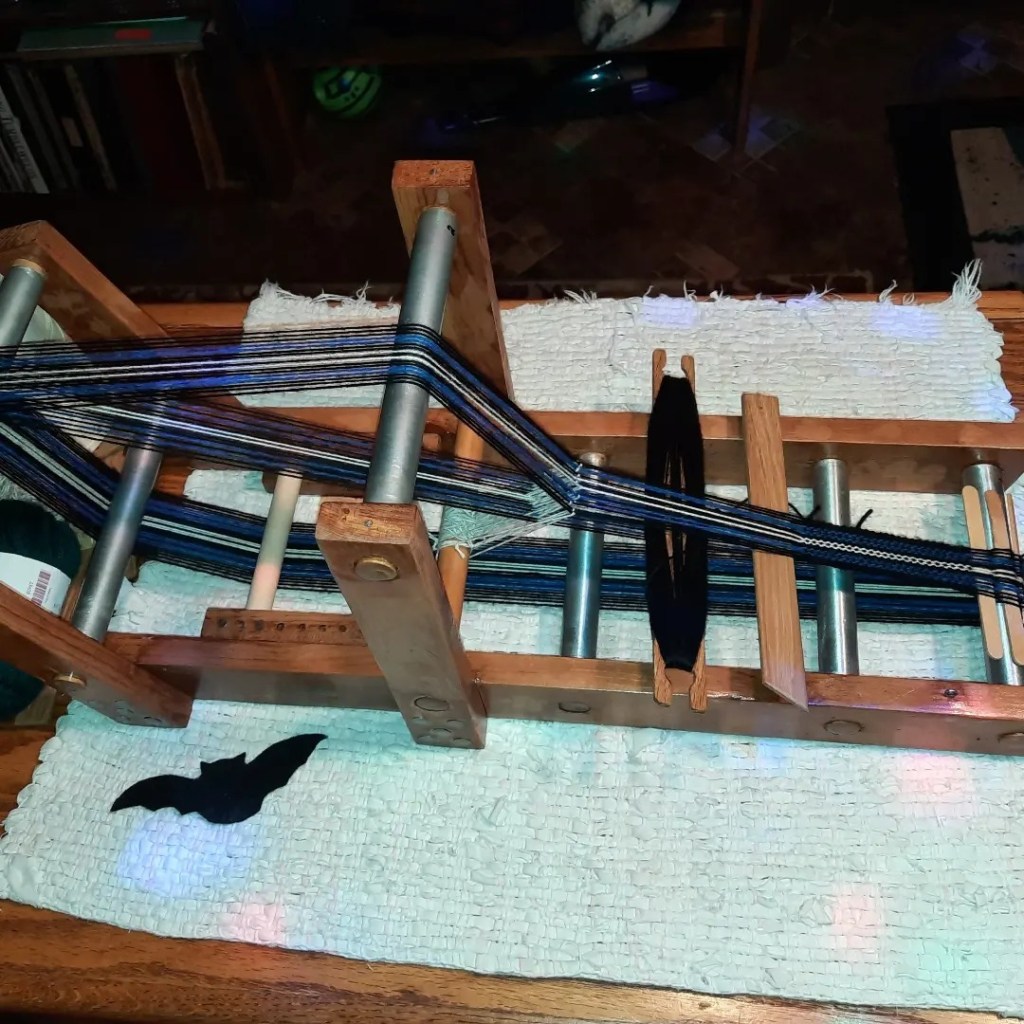

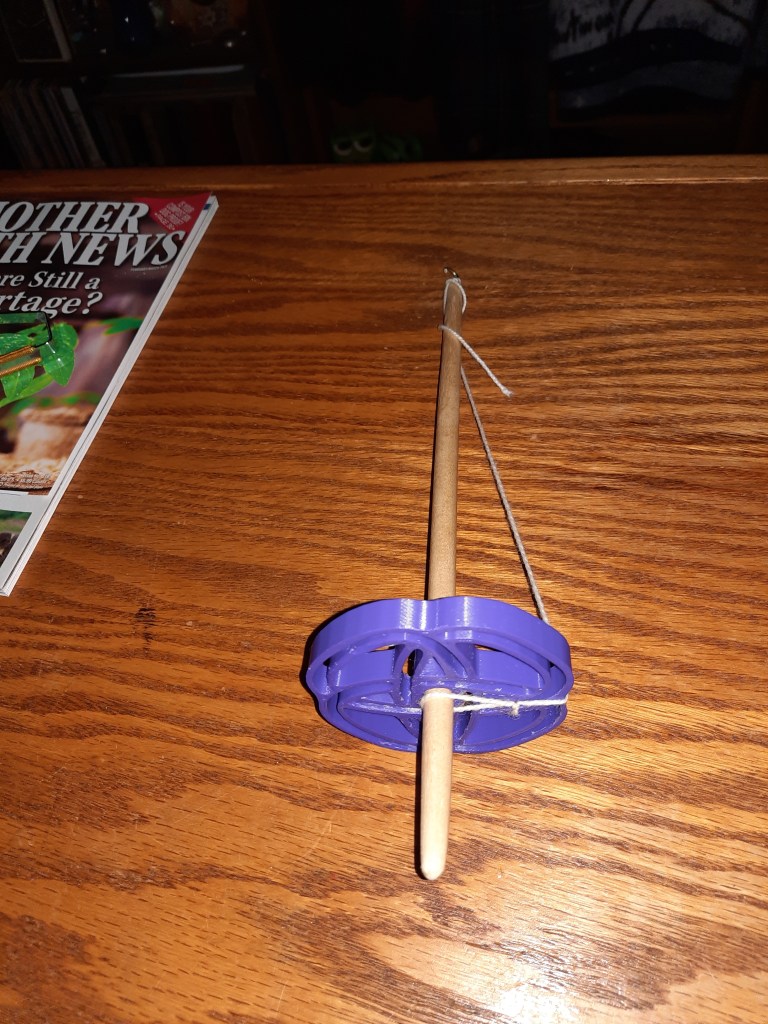

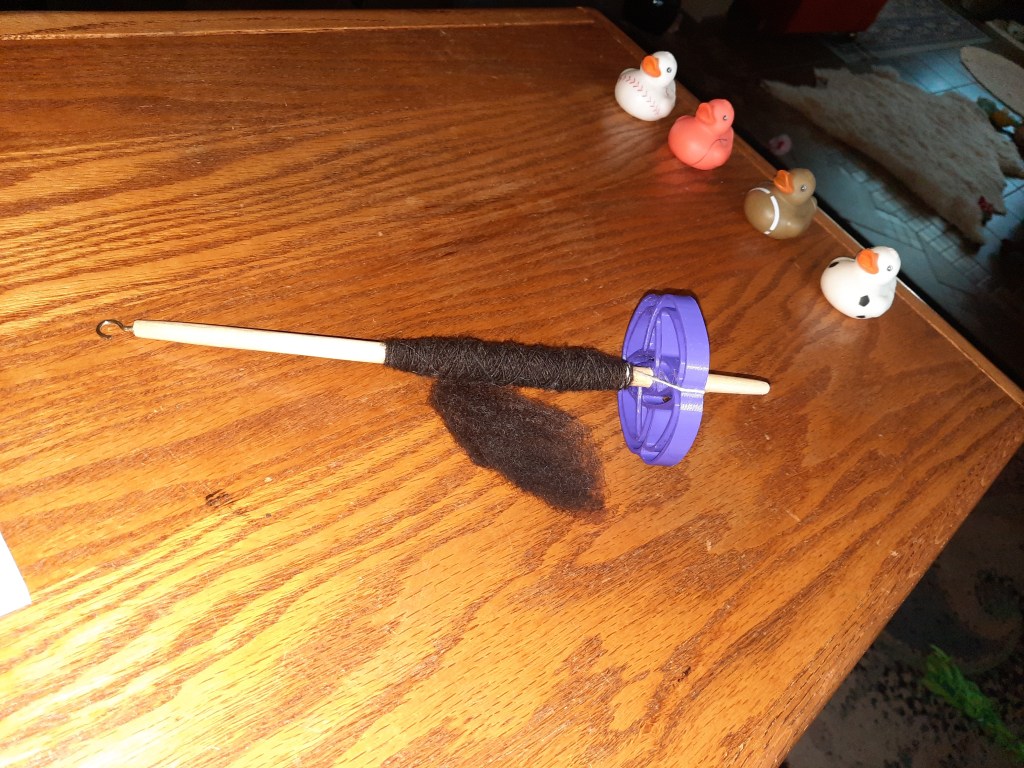

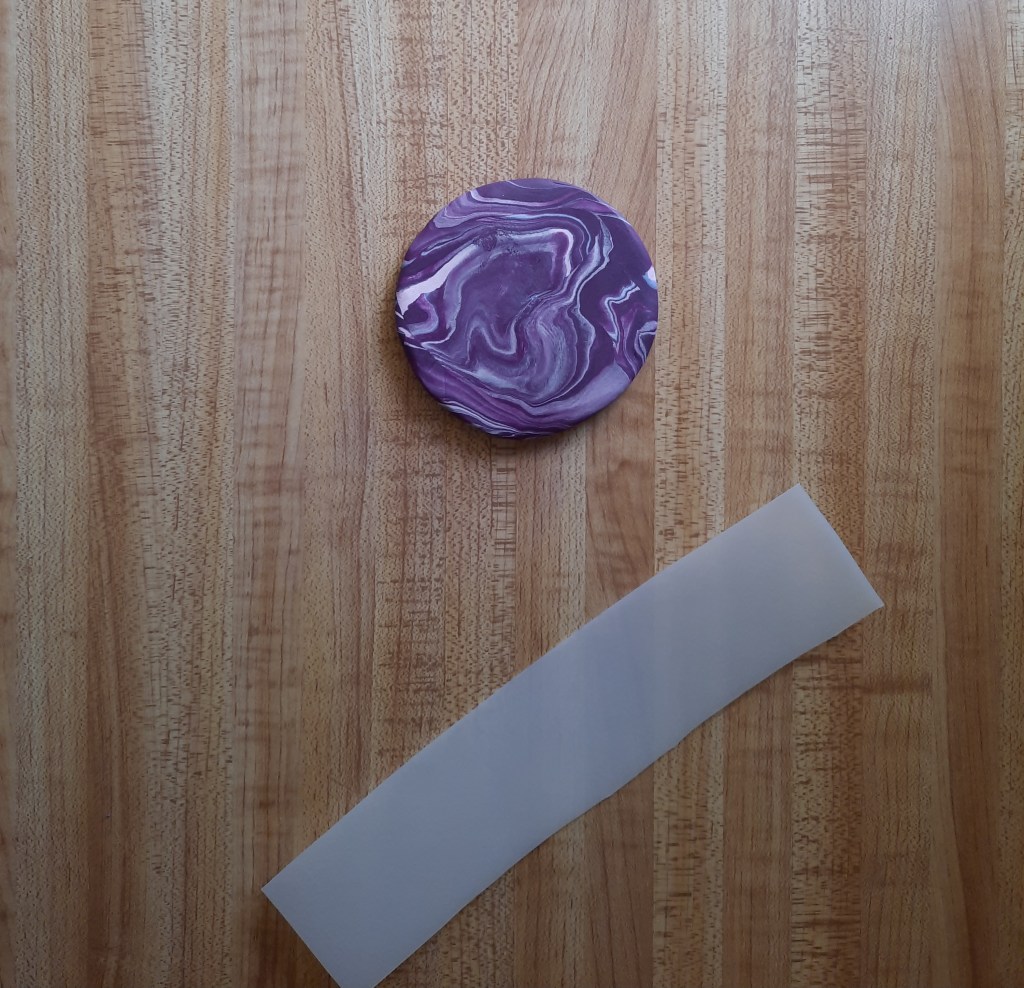

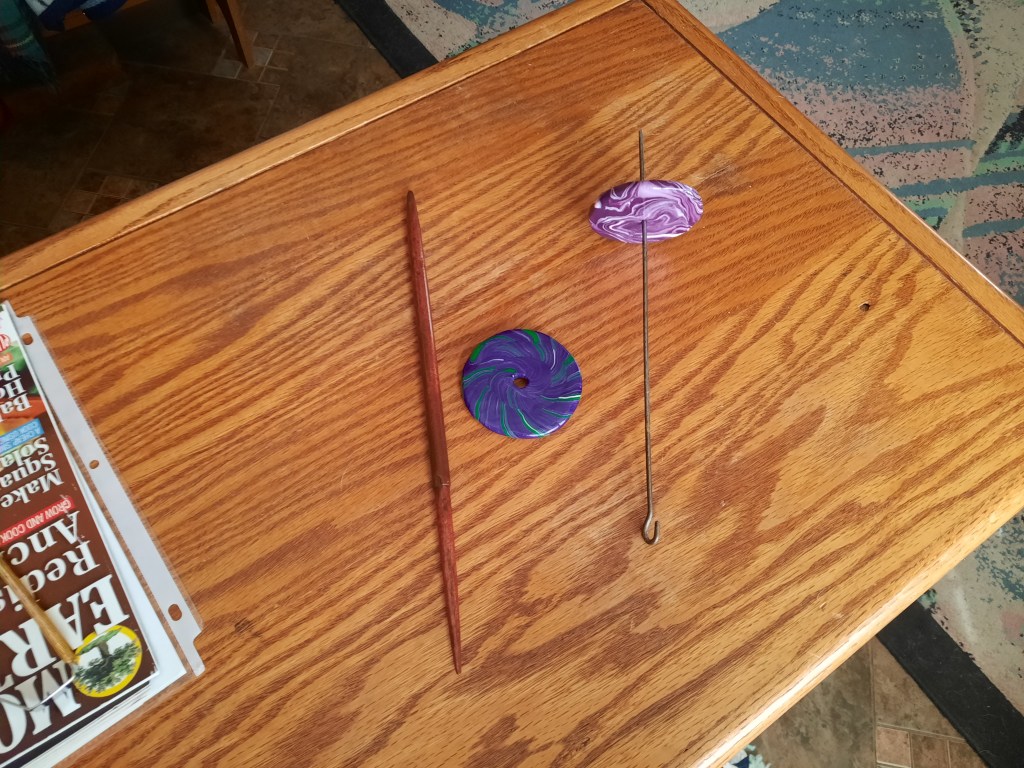

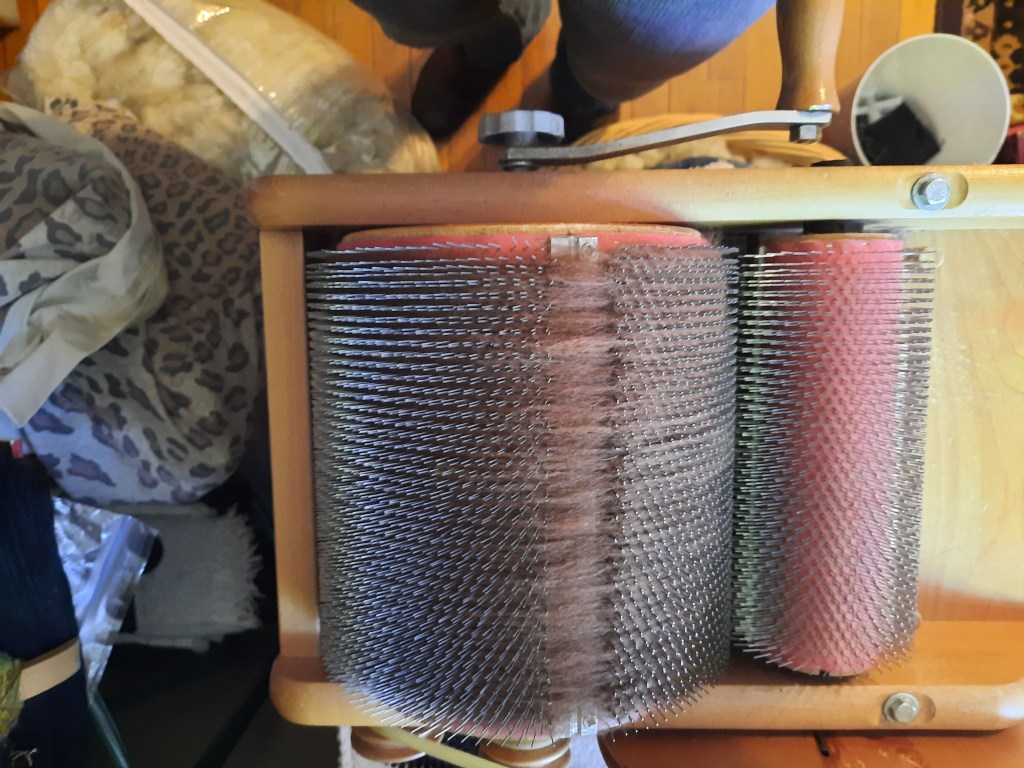

I finished the first belt using this pattern in cream white wool and royal blue sized wool. I rewarped the inkle loom with the cream white and my handspun, handdyed turquiose green wool for the next band/belt.

I graphed a draft of my derivation of the Baltic-13 2 draft and changed the colors for the next belt I will be weaving next. The next image is the weaving draft to be used with the threading chart of Baltic-13 2.

I’ve been warping the inkle loom with 9 extra warp threads (4 up and 5 down) on each side of the pattern(s) because I like more selvage on the edges. This next band/belt will be in dark violet, handspun handdyed light turquoise green, forest green, and the single outside pattern edge in hte dark violet.

When I have time, I’ll post progress pictures on facebook and instagram as I go along.

Get going and make something AMAZING!!! Feel free to use the chart for weaving, knitting, crocheting, etc.