I recently finished a complete restoration of an antique combination sewing stool with storage from 1929 that was originally created for production in 1923. I didn’t take any photos of the original as the fabric was extremely faded and the piece had been ill-used and ill-stored.

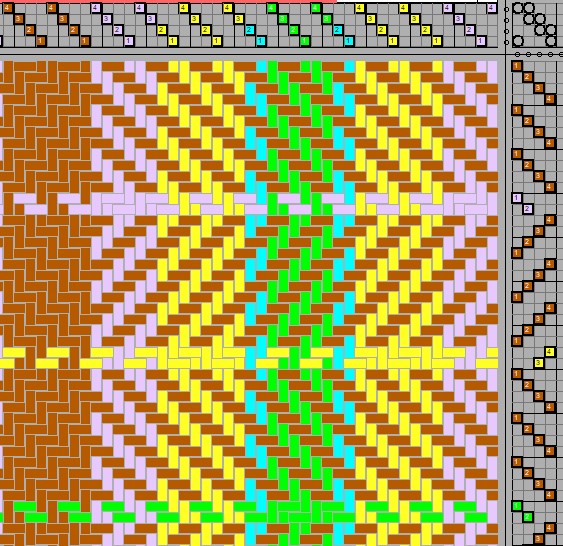

This project was started the week before the Super Bowl and included the removal of asbestos paperboard that the sides were originally made of and reupholstering the sewing stool as well as keeping it as close to the original as possible. The legs are turned oak with metal feet. The frame of the sewing stool is hardwood, however I’m not sure what kind as the paint isn’t chipped anywhere. The corners appear to be hardwood as well.

I finally made the decision to get it completed on Super Bowl Sunday and was able to complete it before the game was over.

I used the original fiberboard material that the lid is made of because after some research I was comfortable knowing that it’s wasn’t asbestos. I also reused all of the hardware, legs, and original label. I discarded the cloth covered asbestos paperboard sides and made double-sided fabric sides.

_________________________________________________________________________

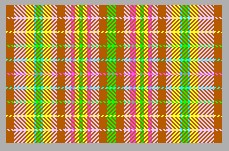

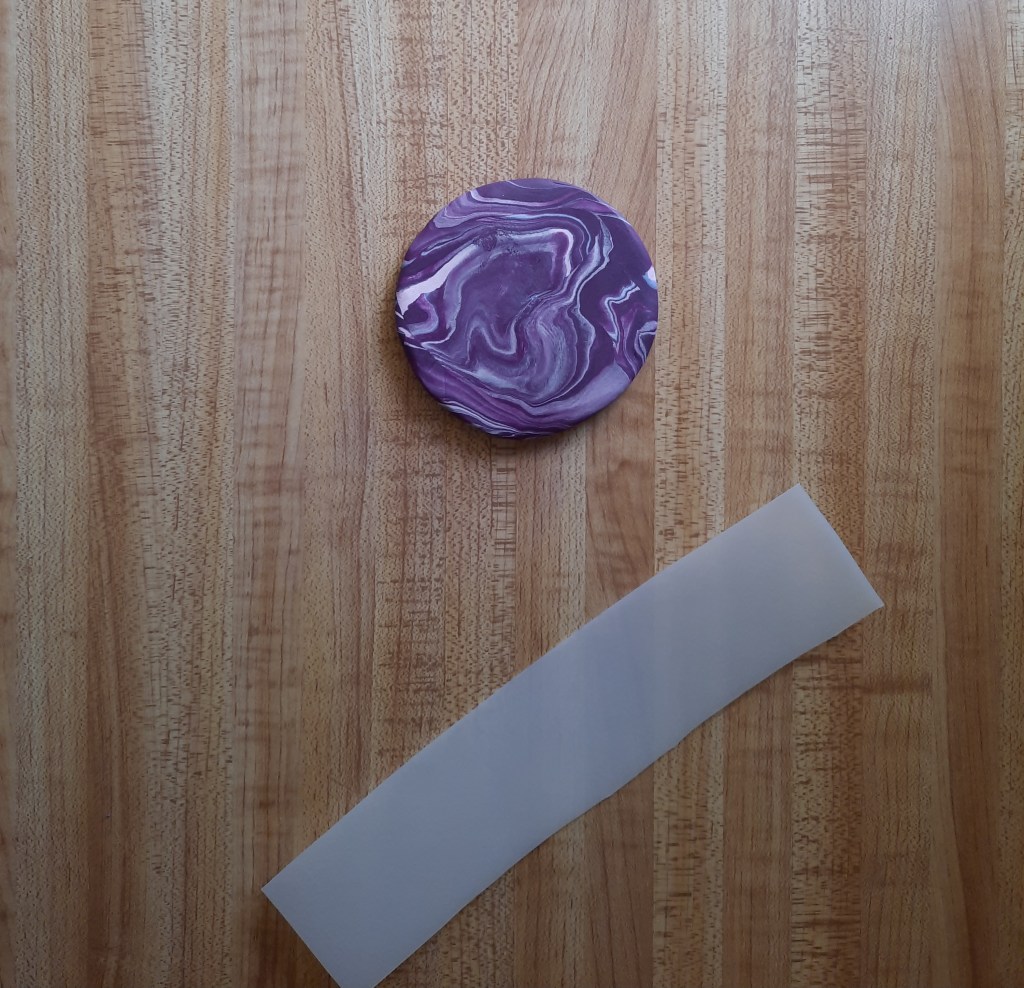

I used all new fabric for the entire restoration, including the same vintage Alexander Henry fabric that I used to make a handsewn pillow cover for a new, handsewn pillow I made back in August of 2022. **See the bottom of the post for the creation photos of the pillow. The fabric for the front and back sides is called “Hot Flash” and is fairly modern.

_________________________________________________________________________

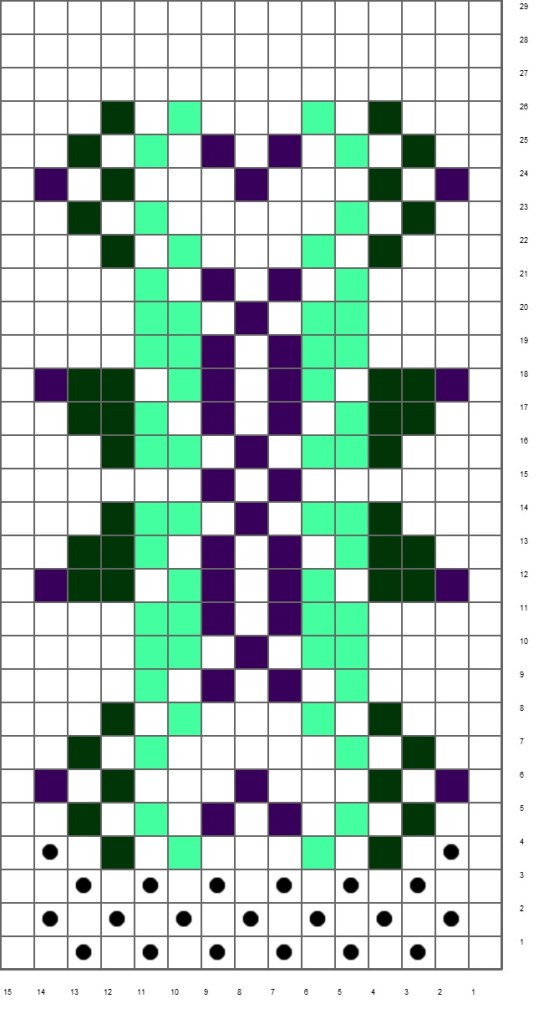

The lid was a bit challenging with the recreation of the elastic storage pockets on the inside of the lid.

_________________________________________________________________________

The sides were sewn together and attached around the frame. I also re-attached the original label to the lid as a reminder that we shouldn’t throw out that which can be restored and/or reupholstered!

_________________________________________________________________________

I brought it downstairs for finishing and I wanted to watch the second half of the Super Bowl! The lid was reattached to the basket base with the original hinges and screws and yes, a bit of wood glue was involved because the wood under the left hinge was cracked (which is typical for a lot of these old pieces). I watched some of the game while the glue dried.

_________________________________________________________________________

I attached the legs after the glue was dry and placed it by my favorite 1950’s chair with the pillow I made featuring the first use of the Alexander Henry fabric.

_________________________________________________________________________

Here are the photos of the pillow project!

What are you waiting for?? Get busy and create something!!!